Crafted Your Way – blending modern precision with traditional craftsmanship to bring your vision to life

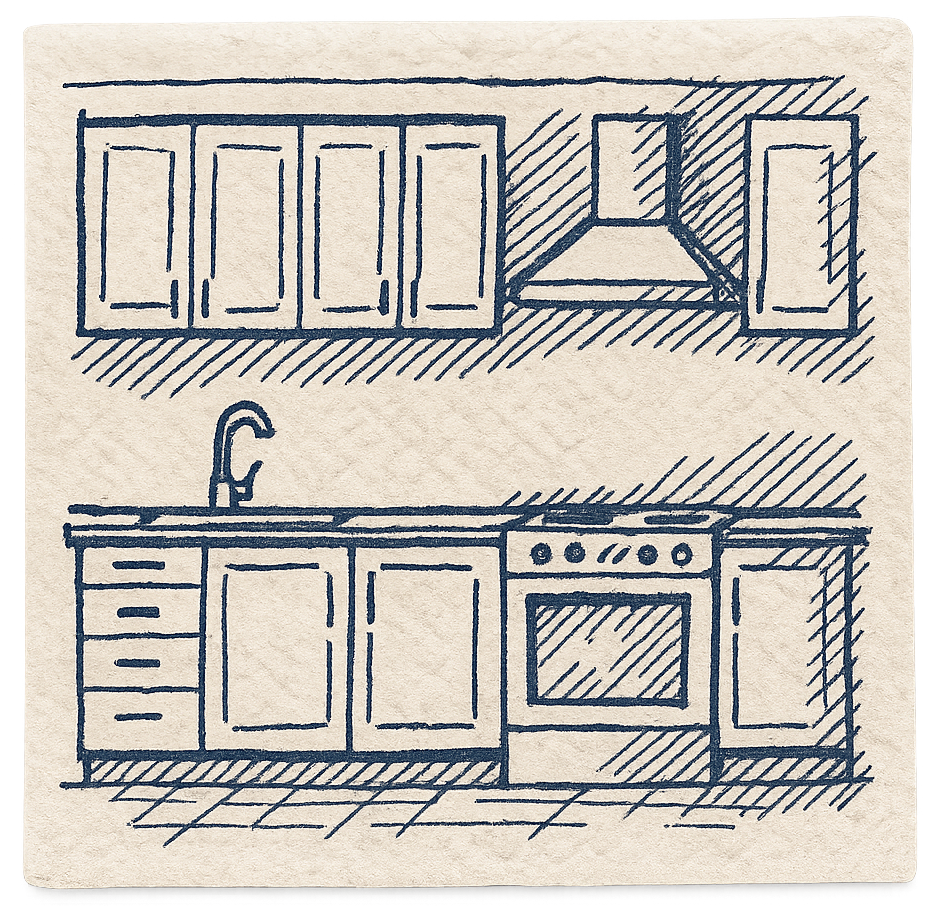

Design & Consultation

Every project begins with an idea — a sketch, a concept, or a set of architectural drawings. Our design team refines those ideas using modern CAD software, producing detailed shop drawings and 3D visual renditions so you can see your project from every angle before production begins. We collaborate closely to fine-tune proportions, features, and functionality, ensuring every detail reflects both craftsmanship and purpose.

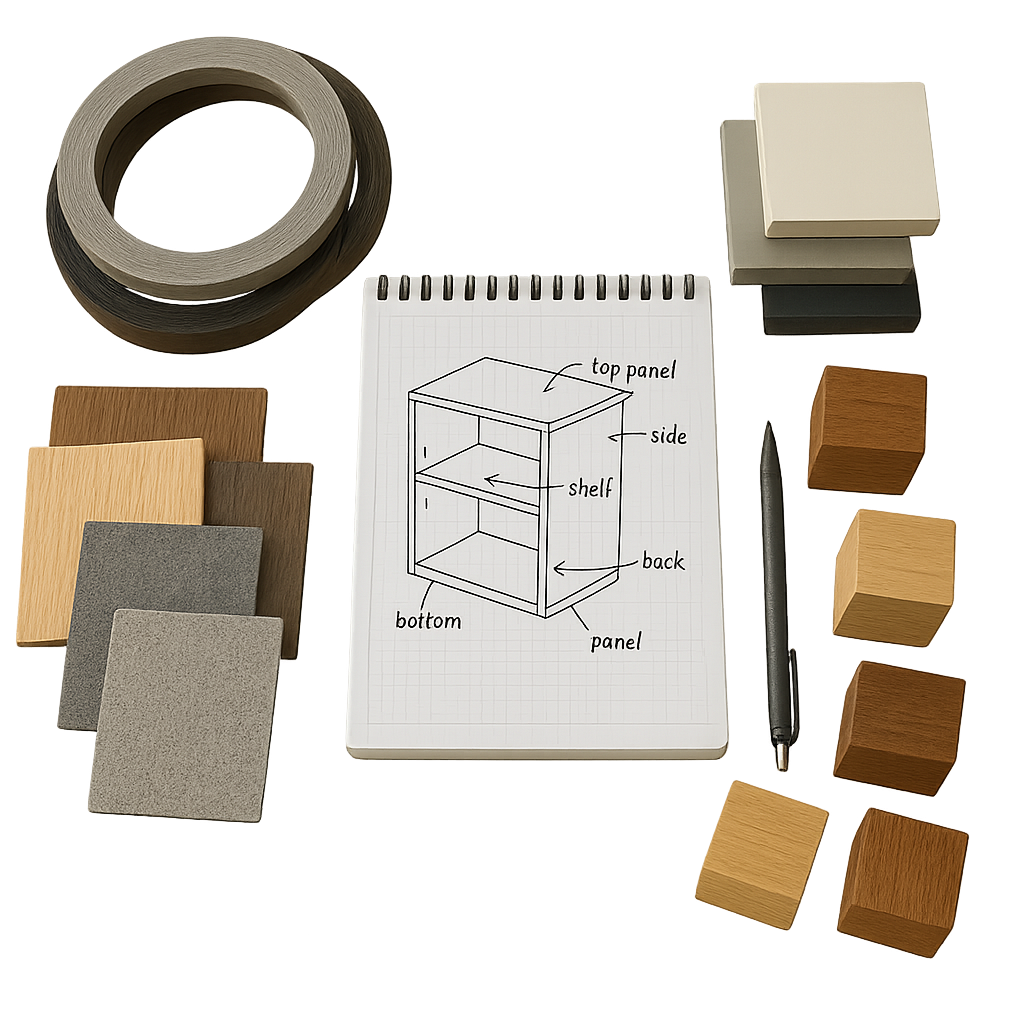

Material Selection

While designs take shape, we guide you through choosing the right materials to achieve your vision. From solid hardwoods and veneers to melamine, laminate, and composite panels, every material is evaluated for its appearance, durability, and application. We can provide samples of raw materials and finished parts that show the actual texture, colour, and finish you can expect in the final product. This hands-on step helps align the design and material choices early, creating a clear foundation for production.

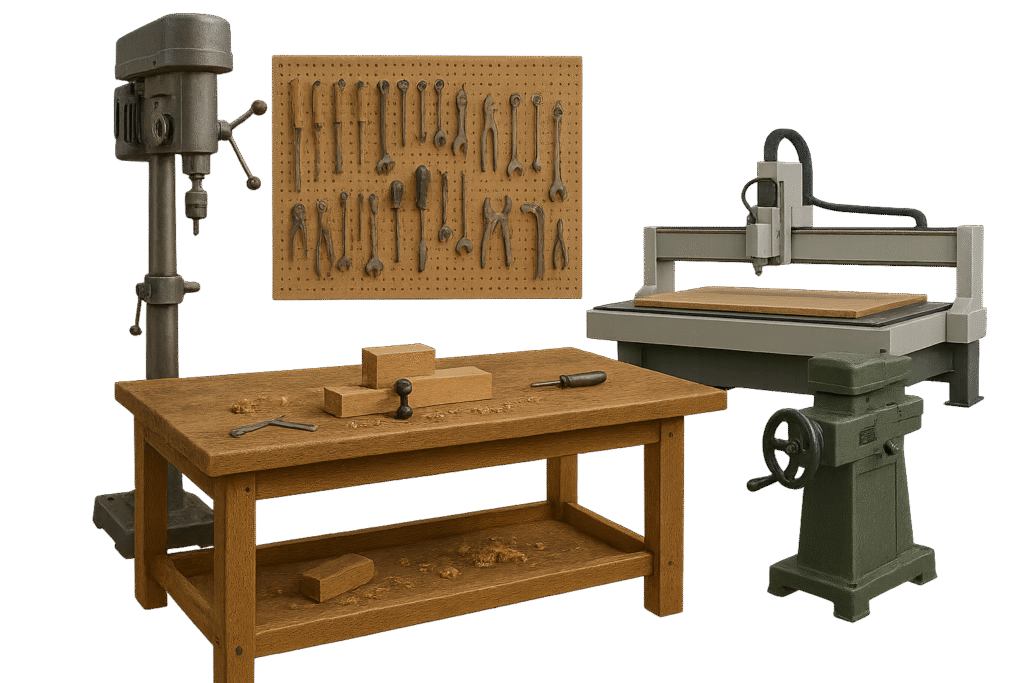

Precision Manufacturing

Once the design and materials are set, production moves to our modern facility, where advanced machinery and skilled craftsmanship work hand in hand. Every component is processed with computer guided machines and precision tooling for consistent, accurate results. Each part is identified with a barcode label and tracked by scanners through every stage of production — from cutting and machining to assembly and finishing. This digital tracking system ensures complete traceability, helping us maintain tight quality control and efficient workflow throughout the manufacturing process.

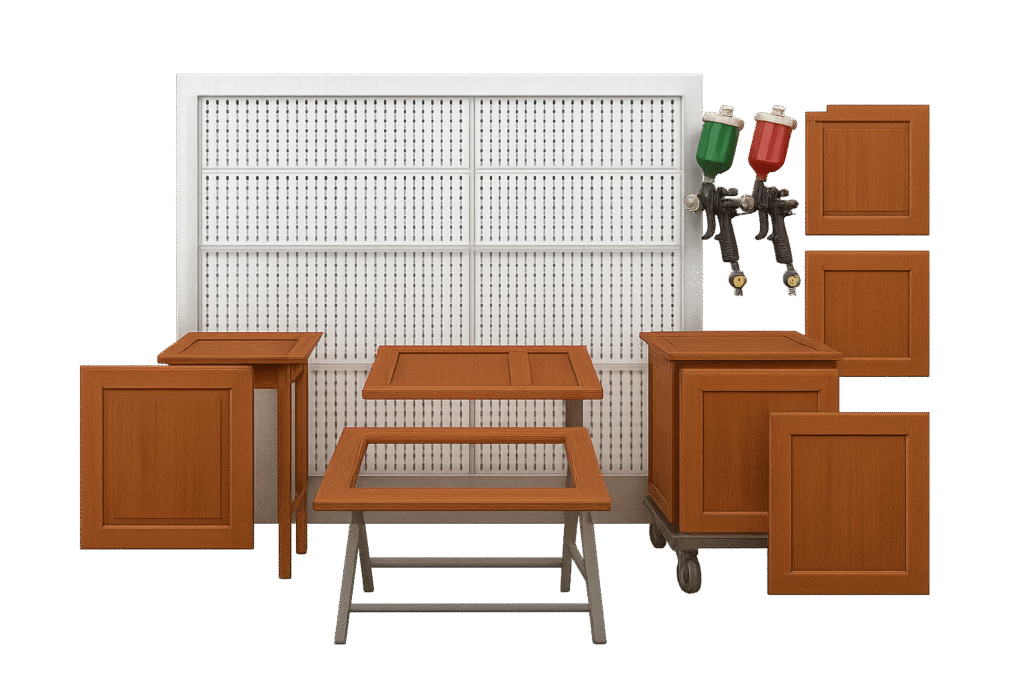

Finishing & Detailing

Once parts are machined, those requiring finishing move to our professional spray booth, equipped with precisely controlled heating and filtration systems originally designed for automotive finishing. This environment ensures clean, even coatings with exceptional durability. Traditional wood components receive stains, paints, or clear finishes, while modern materials may be left as manufactured or treated with specialized surface coatings. Each part is finished to meet its intended appearance and performance, ensuring a consistent, high-quality result across the entire project.

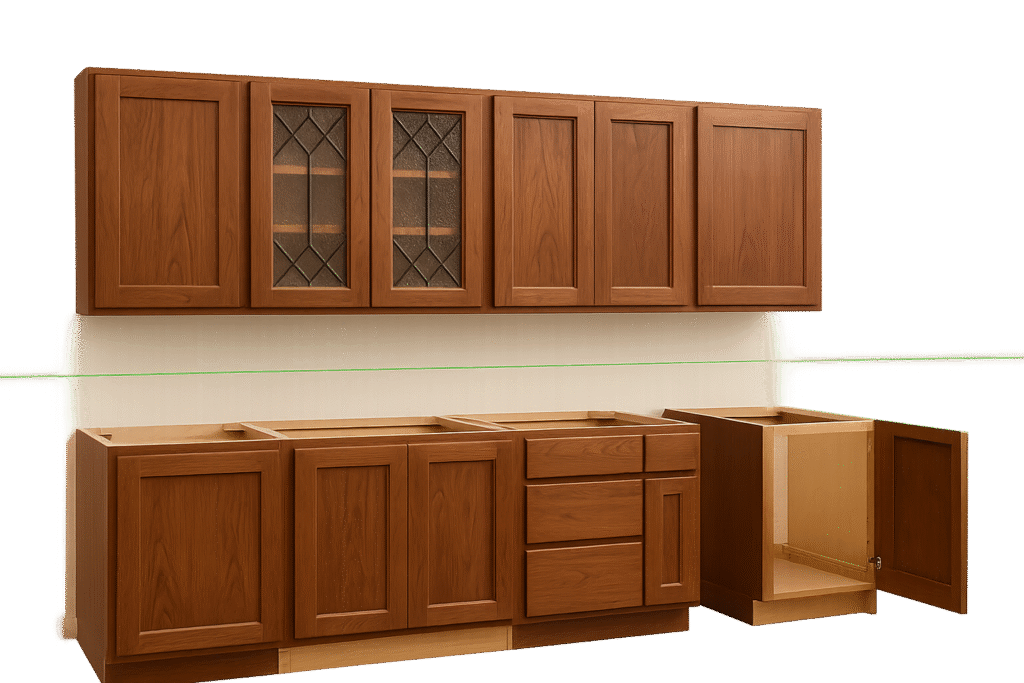

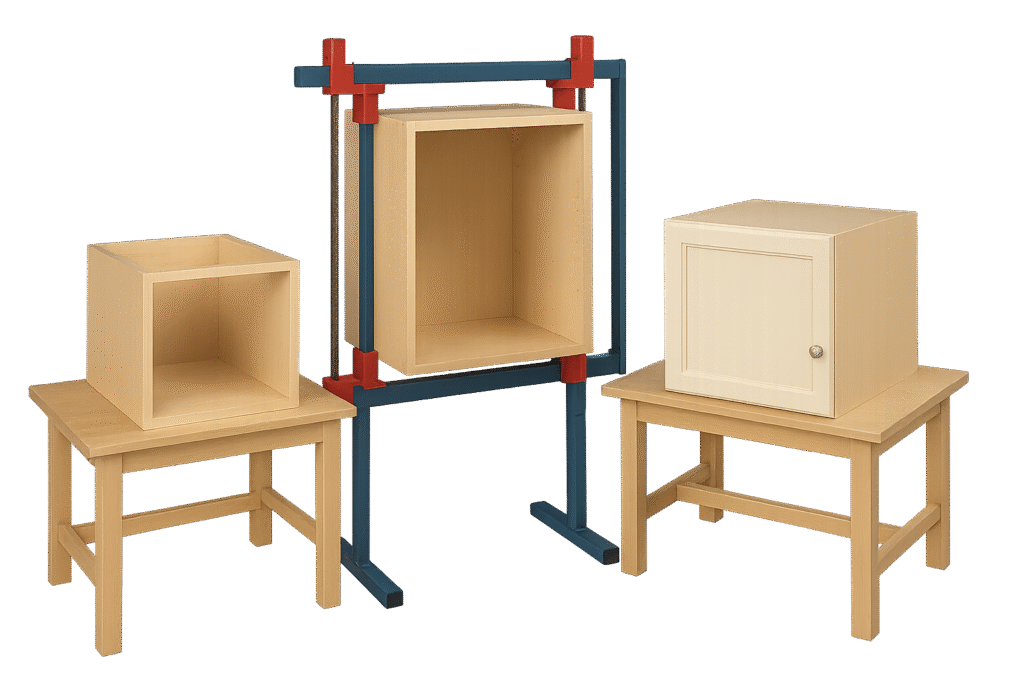

Assembly & Quality Check

Once all components are complete, they come together in our assembly area, where modern precision meets traditional craftsmanship. Each unit is built, aligned, and inspected according to strict architectural standards — the very standards our partners and colleagues helped pioneer within the industry. Every joint, edge, and finish is verified for accuracy and consistency before leaving the shop. This disciplined approach ensures that each product reflects the same precision and integrity designed into it from the start.

Delivery & Installation

Our climate-controlled shop ensures that every product is built and stored in stable conditions before it leaves for installation. Each item is wrapped, protected, and prepared for transport with care. On site, our installation team uses laser technology for precise alignment and modern instruments to monitor temperature and humidity, ensuring the environment meets the same standards as our production floor. Every cabinet and millwork feature is fitted to exact architectural specifications, completing the process with the precision it began with.